LED free-form lens

Date:2018-07-25

LED has become the most common light source today. Because LED has the advantages of small size, fast response, energy saving and environmental protection, it is widely used in road lighting, car headlights and backlight display. These applications require LEDs with high brightness. Color uniformity, but because the LED is a surface light source, the light exit angle is small, making its color uniformity poor.

LED has become the most common light source today. Because LED has the advantages of small size, fast response, energy saving and environmental protection, it is widely used in road lighting, automotive headlights and backlight display. These applications require LEDs with high color uniformity. Sex, but because the LED is a surface light source, the light exit angle is small, making its color uniformity poor. If the existing YAG (yttrium aluminum garnet crystal) phosphor coated LED, there will be a phenomenon that the edge is yellowish and the middle is bluish, and the effect of improving the color uniformity of the LED is poor.

At present, there are two main methods for improving the color uniformity of LEDs: one is to change the coating mode of the phosphor, and the coating is applied away from the coating or conformal coating. The principle of this method is to make the blue light emitted by the LED pass through the same propagation path in the phosphor, so that the yellow light excited at each angle is uniform, thereby achieving the color uniformity of each spatial distribution angle, but the method requires the packaging process. Higher sex, resulting in higher costs. Second, a microlens array is added to the LED chip. However, such optical structures do not provide effective control of large angle optical lines, and after passing through such optical structures, the optical efficiency of such optical structures is reduced due to Fresnel reflection losses and total internal reflection of the optical surface. The existing TIR lens (Total Internal Reflection lens) is mainly used for collimation, thus limiting the divergence angle of the LED, and the existing TIR lens does not improve the color uniformity of the phosphor-coated LED.

In order to solve the above technical problems and obtain LEDs with high light efficiency and high color uniformity, Zhonghuan Quantum has designed an LED free-form surface lens based on total internal reflection through a large number of experimental tests and technical improvements.

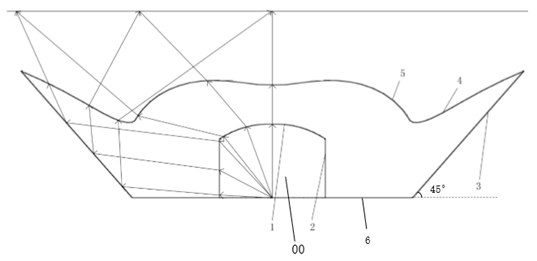

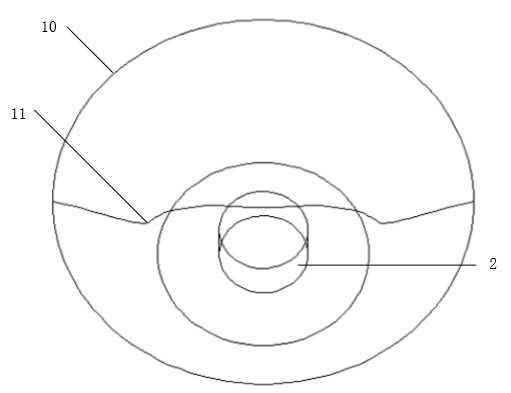

The LED free-form surface lens based on total internal reflection is composed of an incident surface at the bottom, a total reflection surface on both sides, and a free exit curved surface at the top. The incident surface is composed of a refractive cylindrical surface and a refractive arc surface, and the refractive cylindrical surface is formed. And the concave arc surface forms a concave incident cavity for placing the LED light source, and the free exit surface comprises a first free refraction surface and a second free refraction surface, and the upper edge of the total reflection surface is connected with the upper edge of the first free refraction surface Forming a convex outer edge of the lens, the lower edge of the first free refraction curved surface is connected with the edge of the second free refraction curved surface to form a groove, and the total reflection surface and the free exit curved surface constitute an outer contour of the lens.

Compared with the prior art, the LED free-form lens based on total internal reflection has the advantages of low cost and easy processing, and has a larger divergence angle, can achieve higher light efficiency and better than the conventional TIR lens. Color uniformity.

The figure below shows an illustration of this LED-based free-form lens based on total internal reflection:

Figure 1: Front view of an LED free-form surface lens based on total internal reflection

Figure 2: LED free-form surface lens structure based on total internal reflection

【Close】

+86-760-22115926 Anna Zhang

+86-760-22115926 Anna Zhang

gaea668@263.net

gaea668@263.net